Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Published: May 31, 2025

Updated: May 31, 2025

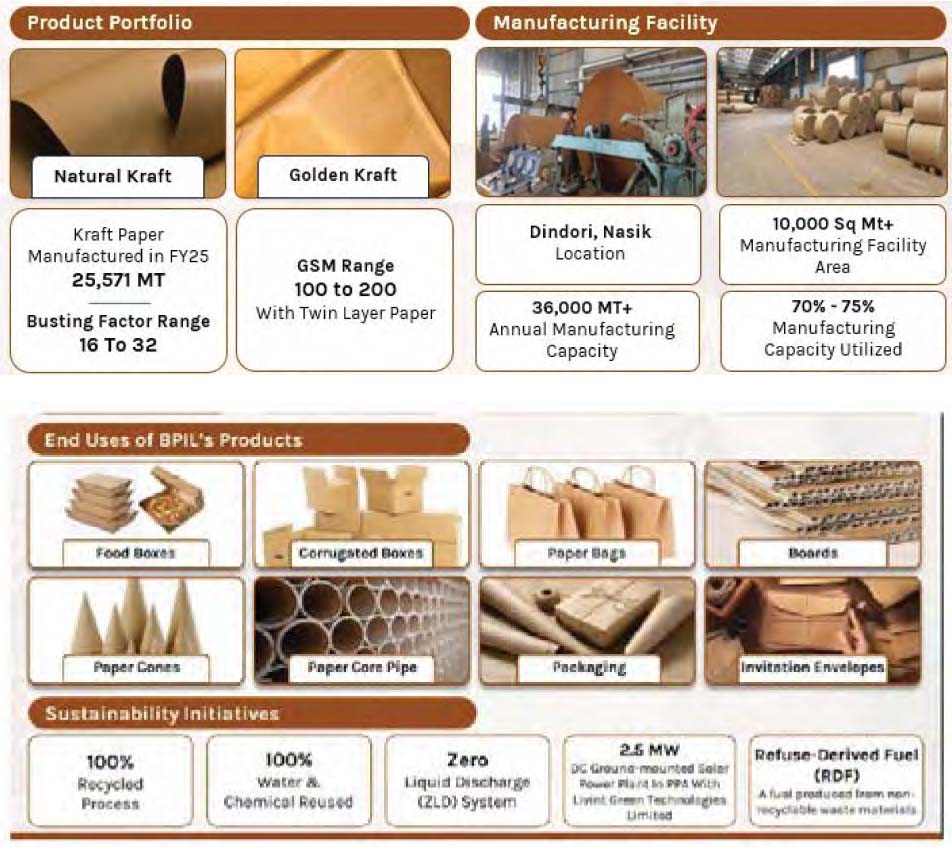

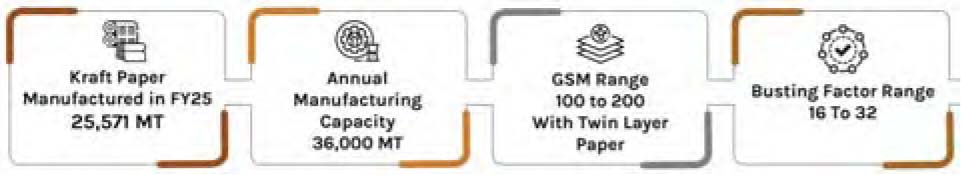

Banganga Paper Industries Limited (BPIL) is one of the leading manufacturers and suppliers of a diverse range of Kraft paper. The company’s wholly owned subsidiary, Banganga Paper Mills, located in Dindori, Nasik, and operates a state-of-the-art facility spread across more than 10,000 square meters. With an installed production capacity of over 100 metric tonnes per day, the facility produces various types of corrugated papers with different GSM ranges, which are fur ther used in the manufacturing of paper bags, pa per cones, boards, and corrugated boxes. Addi tionally, it manufactures a wide range of craft paper, also available in various GSM ranges.

Banganga Paper Industries Limited has advanced its sustainability agenda through a Power Purchase Agreement (PPA) between its subsidiary, Banganga Paper Mills Limited, and Livint Green Technologies Ltd. Under this deal, a 2.5 MW DC ground mounted solar power plant will be developed at Karjat Village, Ahmednagar, to supply clean energy to Banganga’s Nashik unit. In line with captive power generation norms, Banganga will hold a 26% equity stake, with the remainder held by Livint Green. Developed under a Build-Own-Operate model, the plant will ensure reliable, cost-effective green power. A Wheeling and Banking Agreement with the state power utility allows surplus energy to be stored for future use, enhancing energy security and enabling car bon credit benefits.

The 15-year PPA (extendable) reflects the company’s long term renewable energy commitment. With current grid power costing Rs. 10.85/unit, the shift to solar is expected to save Rs. 2.30–Rs. 2.50 per unit, plus a tentative government subsidy of Rs. 1.50/unit. The project goes live on April 1, 2025.

This move will cut fossil-fuel dependency and emissions, align ing Banganga with global sustainability goals. It marks a strong step toward eco-friendly, cost-efficient manufacturing and posi tions the company as a leader in sustainable paper production. Vision: To lead in sustainable paper manufacturing and agri-solutions through innovation, environmental stewardship, and quality excellence.

Banganga Paper Mills Secures MPCB Certification, Reinforces Sustainability Commitment Banganga Paper Industries Limited, through its subsidiary Banganga Paper Mills, has received environmental certification from the Maharashtra Pollution Control Board (MPCB), allowing its Kraft Paper unit to operate until March 31, 2029. The renewal affirms compliance with the Water and Air (Prevention & Control of Pollution) Acts, highlighting the company’s focus on sustainable practices. Key Sustainability Highlights: Refuse-Derived Fuel (RDF): The facility uses RDF, along with coal and agro waste, in its 12 TPH boiler—cutting emissions and reducing dependence on conventional fuels. Zero Liquid Discharge (ZLD): A modern Effluent Treat ment Plant recycles all treated water back into production, ensur ing no wastewater is released externally and conserving water in a drought-prone region. Waste Management: ETP Sludge: Reused as manure or sold for resource recovery. Boiler Ash: Supplied to brick manufacturers for reuse.

These measures not only support environmental goals but also yield economic benefits—saving approximately Rs. 500 per tonne of Kraft paper via reduced water costs, efficient waste han dling, and revenue from recycled by-products. This certification underscores Banganga’s commitment to responsible, efficient, and eco-conscious manufacturing, setting a benchmark for sustainable industry practices.

With an estimated turnover exceeding Rs. 80,000 crore and an installed capacity of 27.15 million tonnes, India's paper industry is a vital contributor to the national economy, accounting for approxi mately 5% of global paper production and contributing around Rs. 5,000 crore to the exchequer. Leading this sector in sustainable practices is Banganga Paper Industries Limited. BPIL demonstrates a balanced approach to environmentally responsible manufactur ing by systematically integrating waste-to-energy solutions, Zero Liq uid Discharge (ZLD) processes, comprehensive by-product utiliza tion, and strategic renewable energy procurement. These initiatives not only ensure regulatory compliance and generate cost savings but also solidify BPIL's position as an environmental leader within the Indian paper industry.

February 15, 2026 - First Issue

Industry Review

Want to Subscribe?

Read Corporate India and add to your Business Intelligence

![]() Unlock Unlimited Access

Unlock Unlimited Access

Lighter Vein

Popular Stories

Archives